Using SHT patented technologies such as our side gap and bank coil production methods, we offer choke coils with wound cores that incorporate grain oriented electrical steel for a wide range of applications.

Characteristics

Toroidal choke coils are taken to a new level using machines for coil winding!

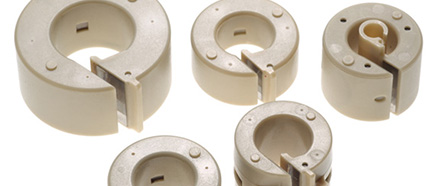

- Molded core

- High quality, high-performance cores are manufactured in a single continuous process, from unspooling thin silicon steel sheet to monolithic molding.

- Side gap (patented manufacturing method)

- Transitioning to machines for winding toroidal choke coils is achieved through by adjusting the magnetic gap position in the coil assembly.

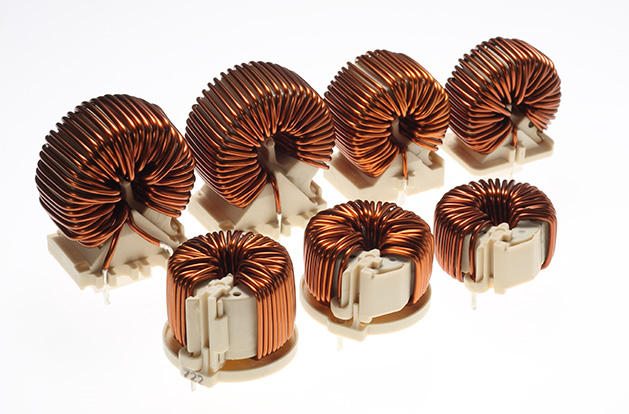

- Bank coils (patented manufacturing method)

- High function mechanical coil windings structurally suppress line potential differences, feature a high withstand voltage and low stray capacitance, and are free of layer short circuits.

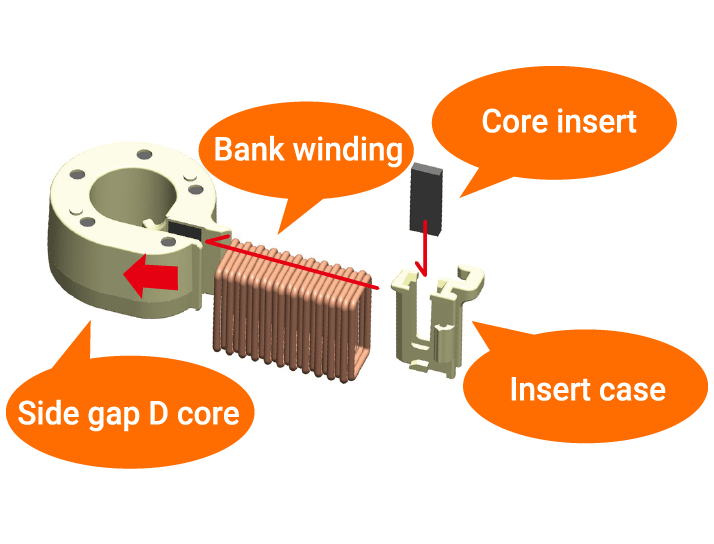

- D-shaped cores (patented manufacturing method)

- Dual magnetic gap structure enables using wire diameters compatible with increasing the rated current range and reduces magnetic flux leakage, thereby reducing unit power loss and [electromagnetic?] noise affecting peripheral equipment.

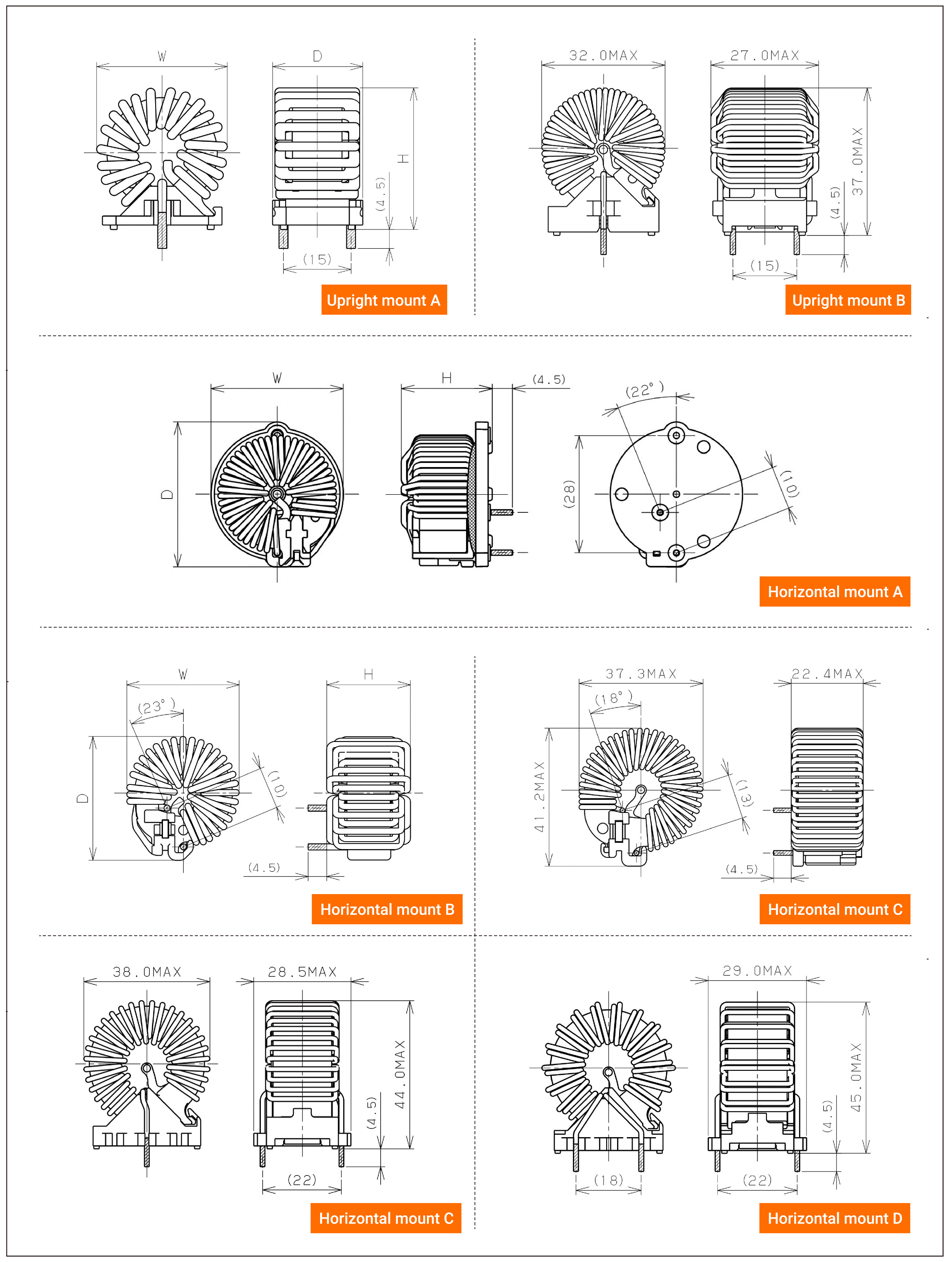

- Multi-pitch lead forming

- Assures compatibility with the user's circuit board design.

- Compact design and low loss characteristics achieved while maintaining the outstanding performance of silicon steel toroidal cores.

- Automatic winding of bank coils using our proprietary production equipment.

- Improved product reliability

- Lower stray capacitance improves frequency characteristics

- Suppressing the electric potential difference between windings means a higher withstand voltage.

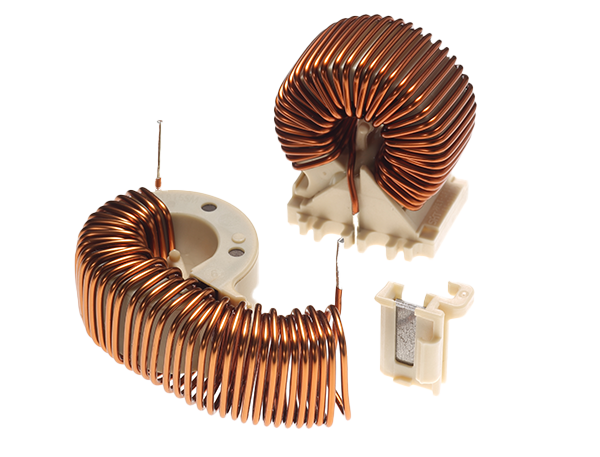

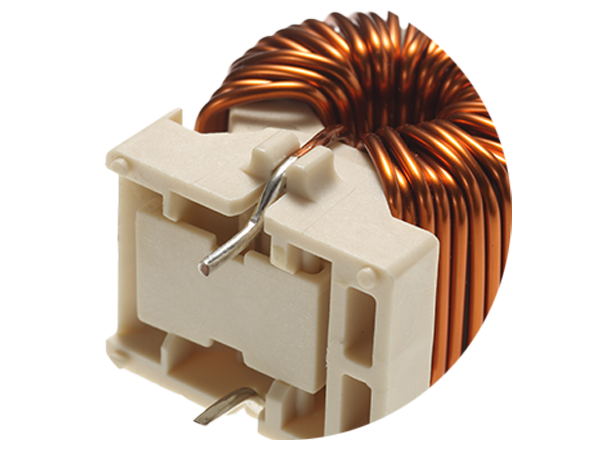

Structure

D-shaped choke coil construction

Configuration

Appearance

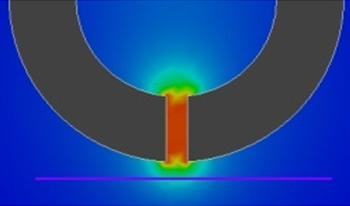

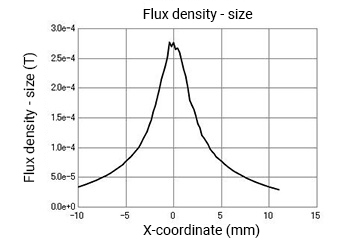

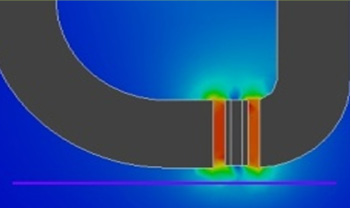

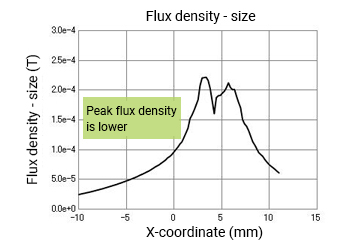

Superior magnetic flux leakage of D core with core insert compared with conventional toroidal core

Conventional

Magnetic simulation

Center gap (toroidal core)

D core

Magnetic simulation

2-stage gap (D core with core insert)

Applications

- Normal mode line filter choke coils for power circuits

- Choke coils for switching power output smoothing circuits

- Choke coils for power factor correction (PFC) circuits, and choke coils for high frequency drive circuits

Product data

Mass-produced product numbers and corresponding electrical characteristics and dimensions

DC superimposition characteristic (L–I at 1 kHz)

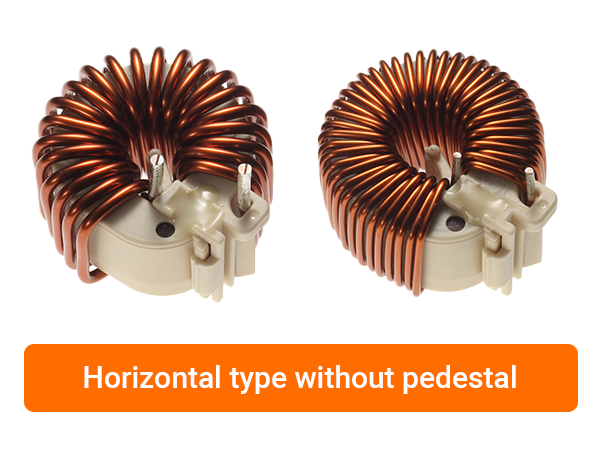

Appearance

Please feel free to ask about other products not shown. We can customize to your specifications.

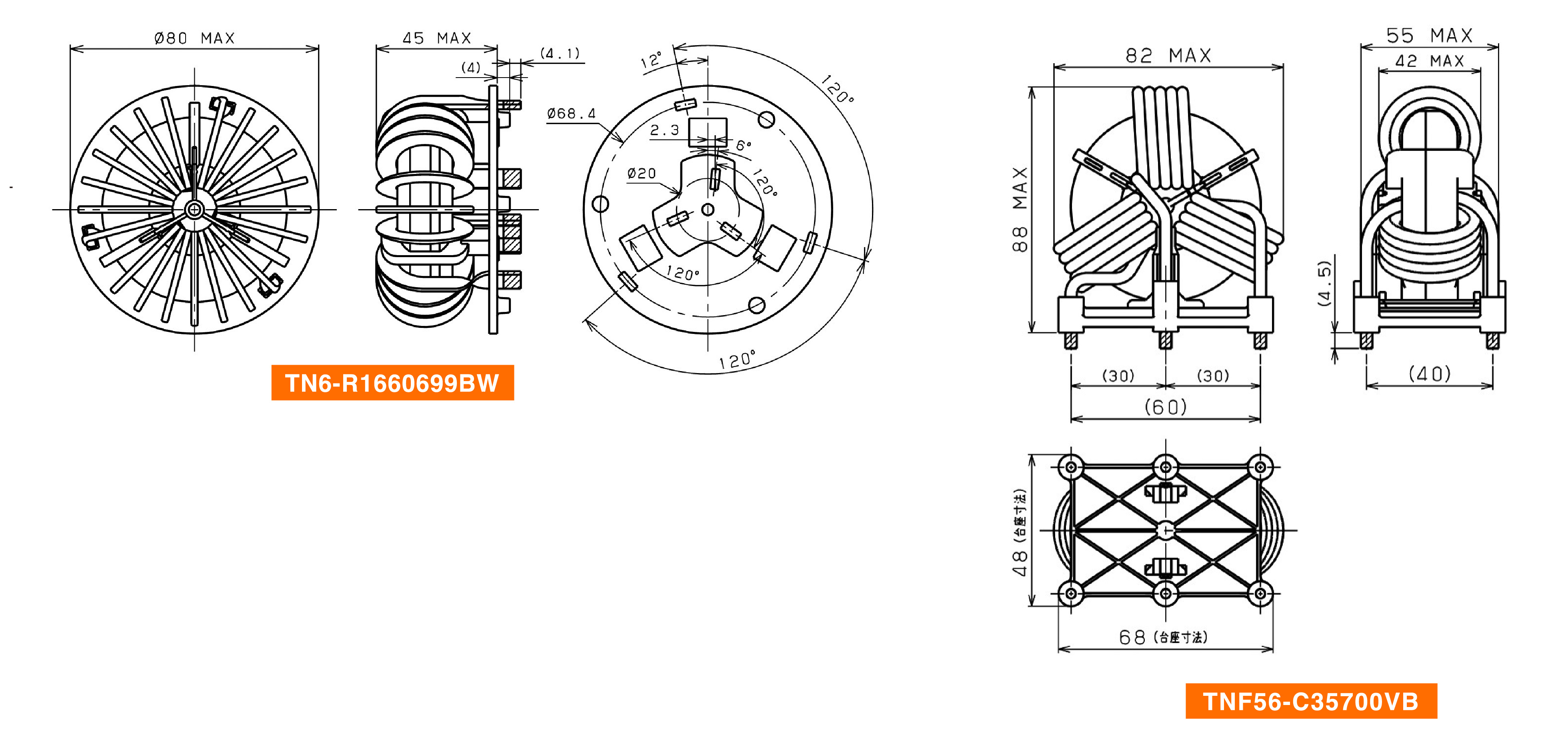

Machine winding, 3-phase common mode choke coils

3-phase common mode choke coils wound by machine!

- Single strand machine windings for high current loads that cannot be wound by hand

- Winding configuration provides superior frequency characteristics

- Machine windings provide more stable quality

- Patented

Product data

Mass-produced product numbers and corresponding electrical characteristics and dimensions

Appearance

Impedance–frequency characteristic (Z–f)