Providing solutions a step beyond customer needs through the synergy of our unique technologies.

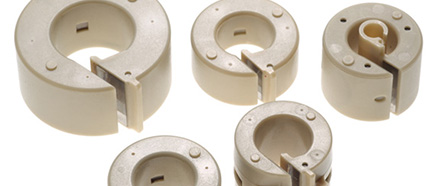

(1) Cores

Characteristics

- Integrated production of everything from winding/press lamination of the ribbon materials to annealing and product completion.

- In addition to core shape and dimensions, we also manage and confirm the required magnetic characteristics.

- We are able to propose suitable materials such as grain-oriented and non-oriented electrical steel sheets and amorphous steel.

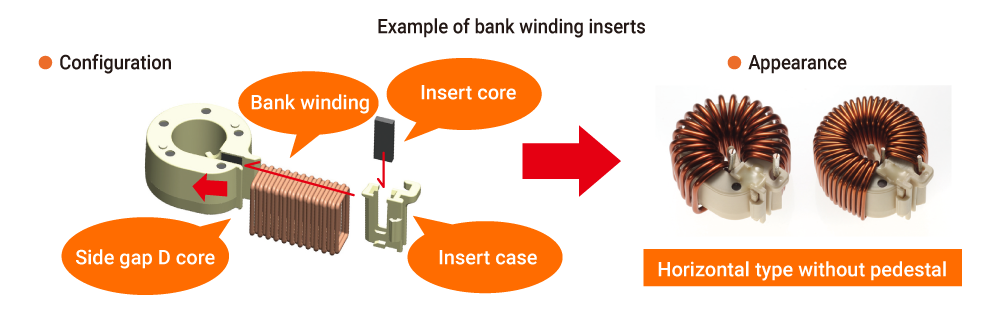

(2) Injection molding

Characteristics

- We can do everything from core forming to injection molding (integral molding and casing) in-house for maximum structural efficiency and miniaturization.

- We propose the optimal structure for minimizing changes in magnetic properties due to molding.

- High dimensional accuracy is achieved for molded products by resin molding of the Wound core.

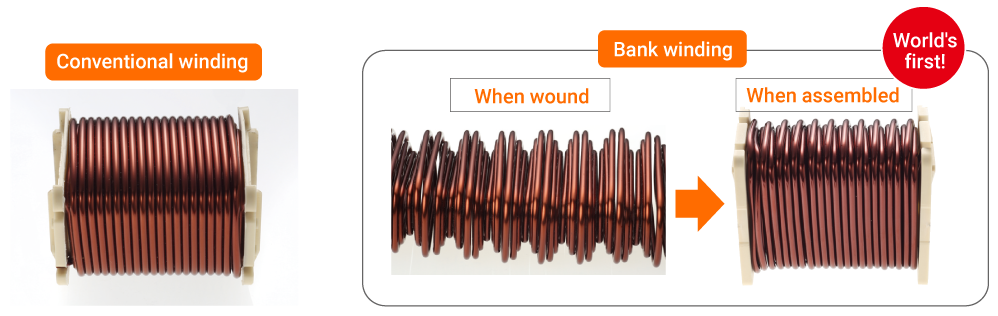

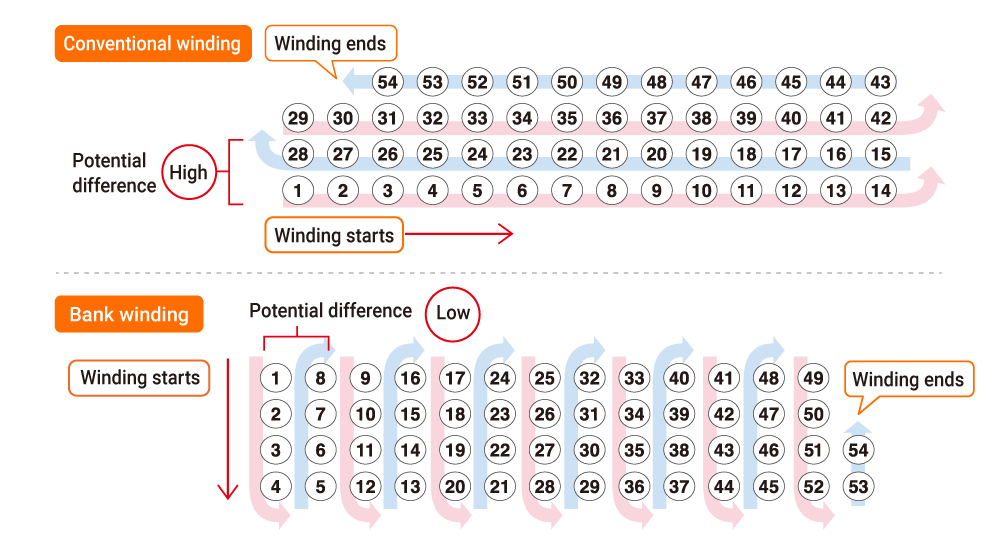

(3) Bank winding (mechanization of winding)

Characteristics

Patented manufacturing method

- The electrical potential difference between windings is extremely small, dramatically improving reliability and safety.

- Stray capacitance is reduced to 1/10 that of conventional winding, greatly improving noise characteristics.

- The appropriate number of turns for the wire gauge can be made using common copper wire.

- The proprietary construction method and winding machine were developed in-house and patented.