Our Craftsmanship

-

(1) Material inspection

Materials are stored under the appropriate conditions and quality inspections are performed prior to use.

-

(2) Core winding

Core winding process

Electromagnetic steel sheet is wound to form cores. -

(3) Annealing

Annealing process

Cores are heat-treated at a high temperature in an annealing furnace to relieve mechanical strain and restore the magnetic properties to ensure high performance. -

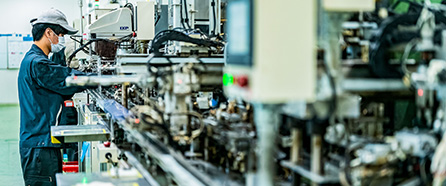

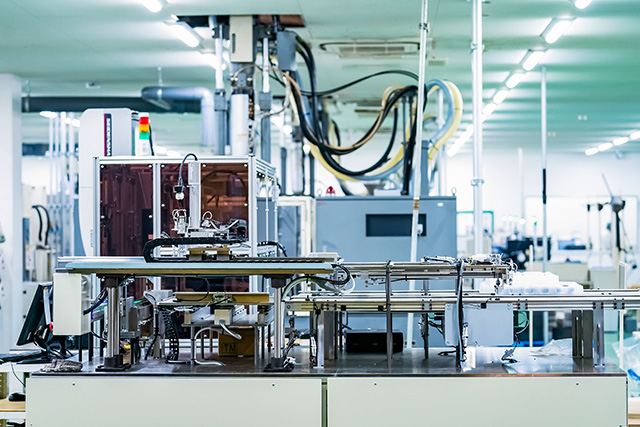

(4) Varnish impregnation and curing

Automated varnish impregnation process

Heat-treated cores are impregnated with varnish. -

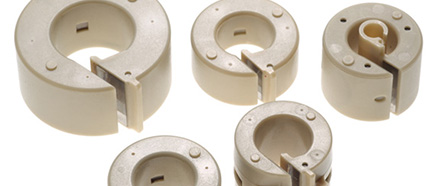

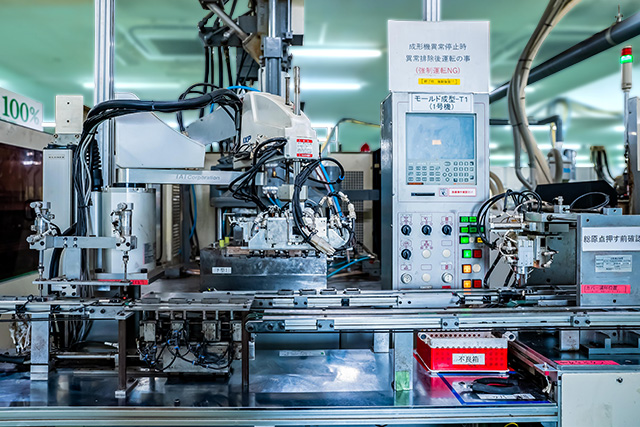

(5) Molding

Molding process

Cores are partially molded with resin. -

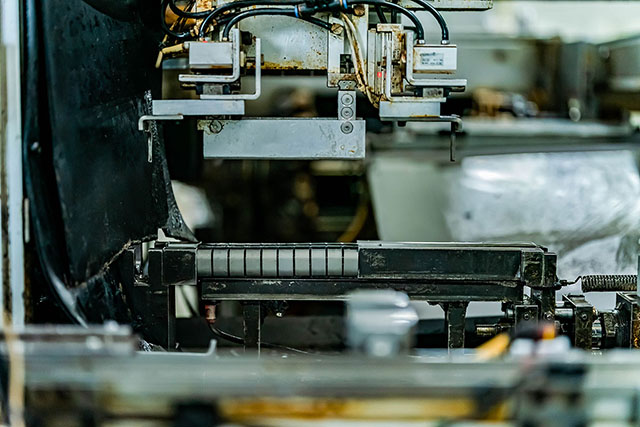

(6) Gap cutting

Gap cutting process

A portion of the each partially molded core is cut to create a gap. -

(7) Ultrasonic welding

Cores are automatically housed in cases and ultrasonic welding is performed.

-

(8) Final inspection

Each sensor core is inspected by an automatic inspection system and the cores are arranged in trays.

-

(9) Quality Assurance

Quality is assured by verifying factors such as a product’s magnetic characteristics.