Product Characteristics

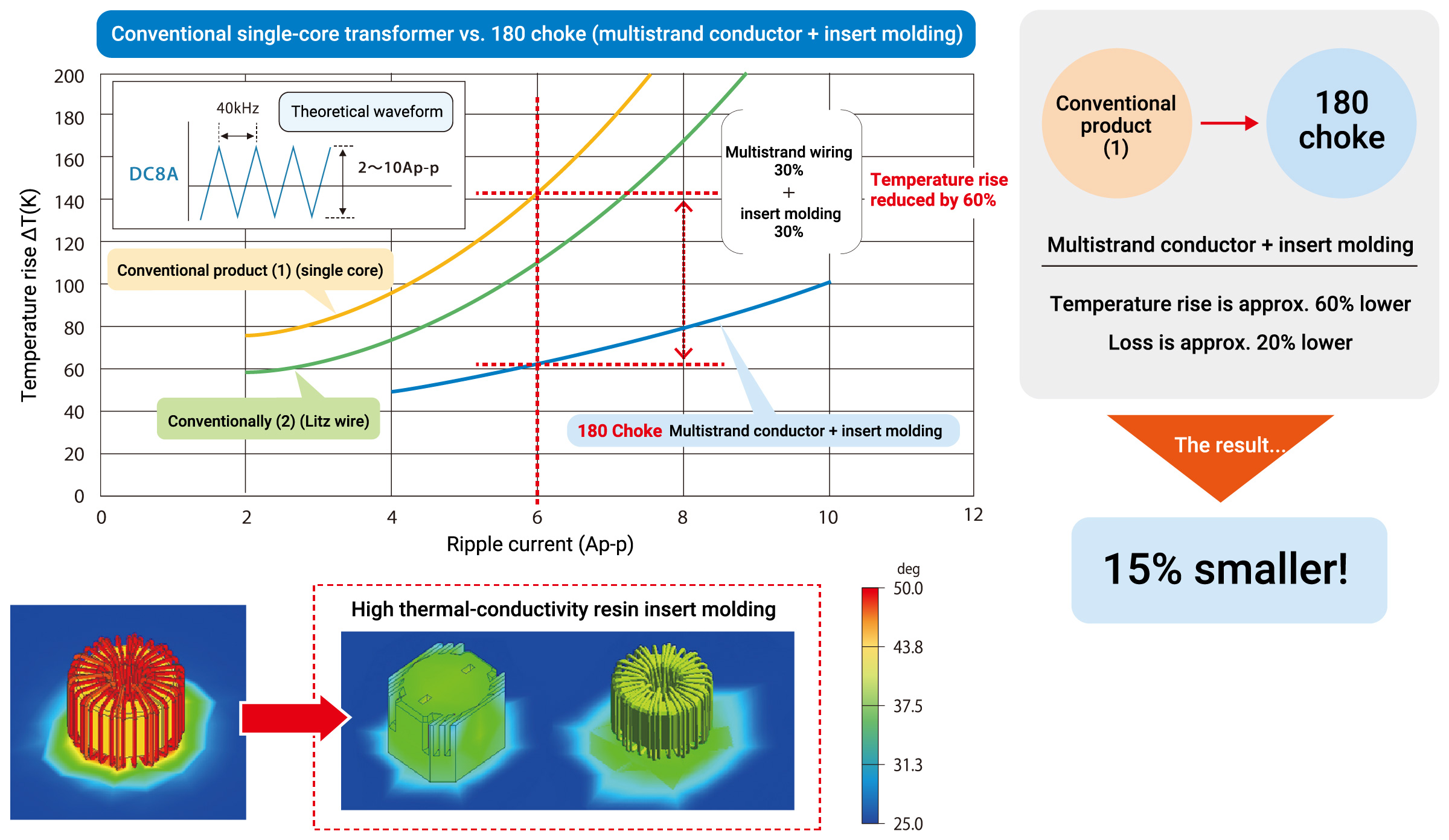

Significantly smaller size and less loss than a conventional model

Higher switching frequency compatibility and reduced weight contribute to lower energy consumption.

-

Low loss

A proprietary method of winding an assembly of untwisted wires achieves both reduced loss using the skin effect at high frequencies and a high space factor for the wound wire

-

Compact and lightweight

Proprietary winding technology and a high heat dissipation design enable a core volume 15% smaller than a hand-wound choke coil.

-

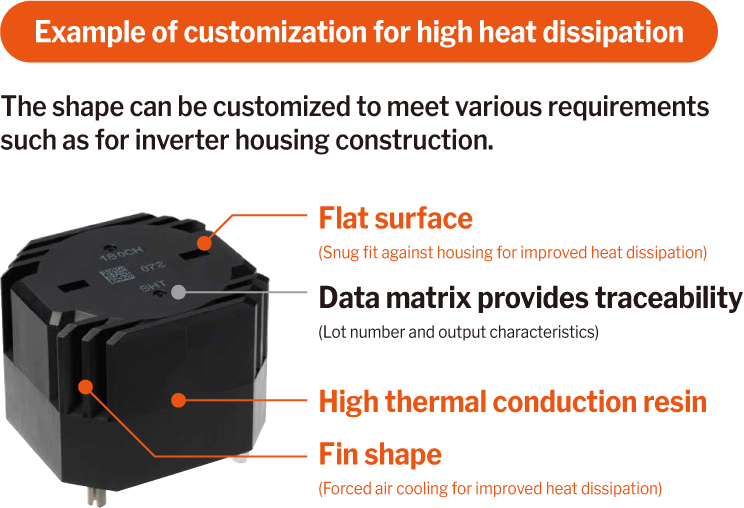

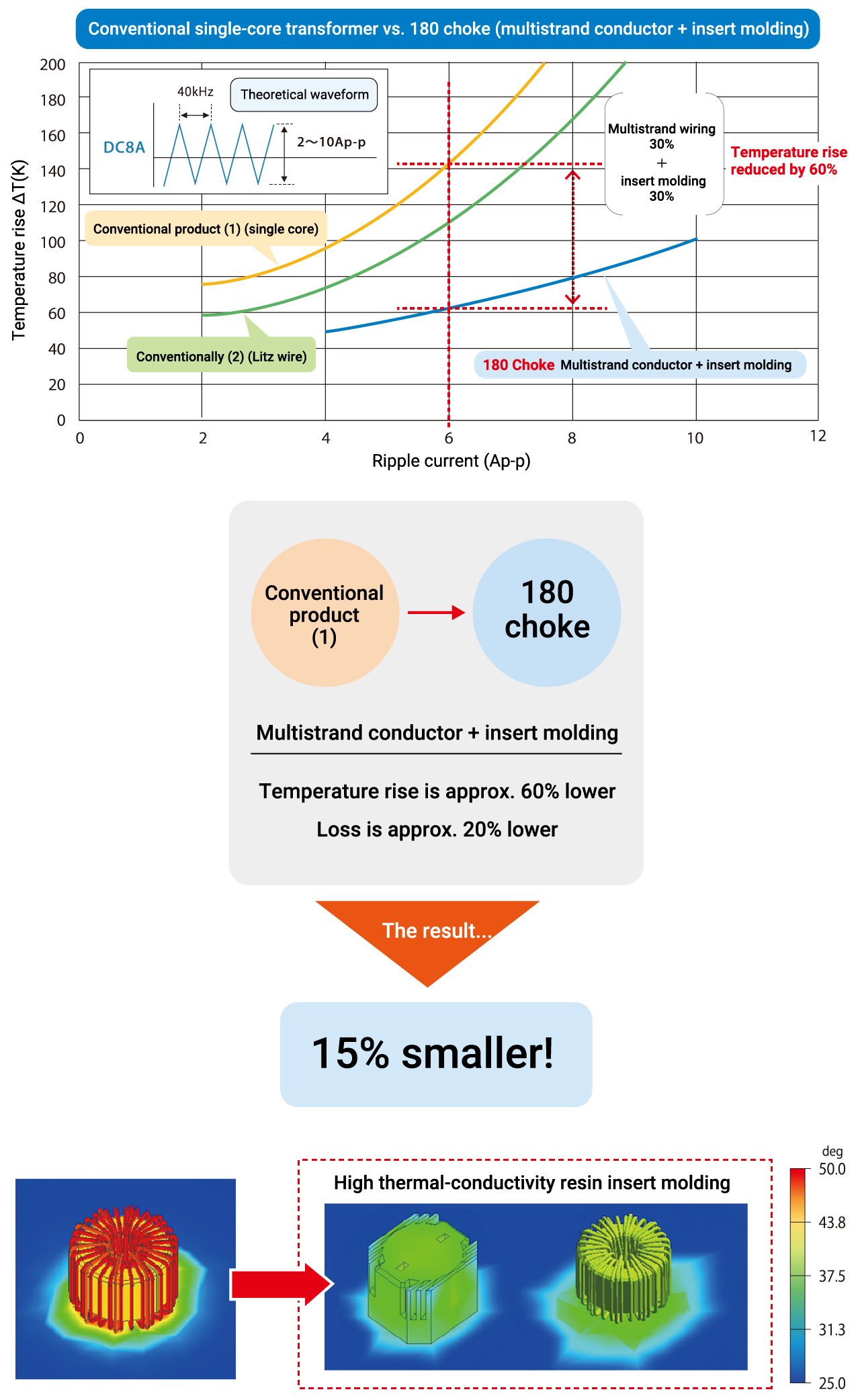

High heat dissipation

Monolithically molded cores using high thermal conduction resin enable thermal equalization and new possibilities for fin shapes, etc., aiding heat dissipation.

Patent pending

Typical characteristics

Shape diagram

Compact design

- Low-loss, high-heat-dissipation design reduces core size approx.

15% (compared with common single-strand iron powder core choke coil).

Designed for mounting on circuit boards

- Monolithic molding evens heat dissipation, reduces size and weight, suppresses temperature rise and enables circuit board mounting

- Enables heat dissipation to chassis through its flat top.

Printed data matrix

- Data matrix enables displaying the lot number and characteristics onscreen; useful for unit control and easy traceability