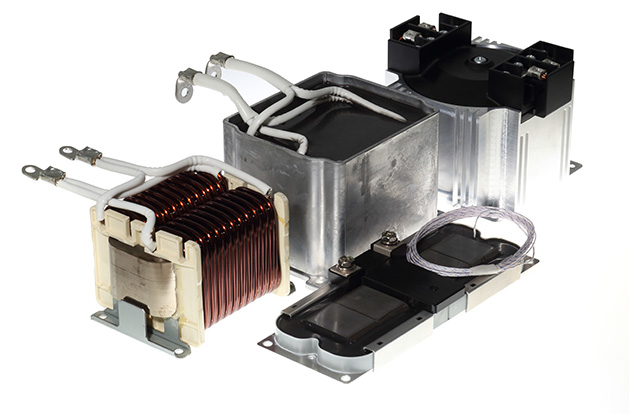

Using proprietary manufacturing methods combining leading-edge technologies, SHT flexibly customizes reactors to meet a wide range of customer needs, including reducing flux leakage and contributing to high unit efficiency.

Characteristics

Hybrid magnetic material reactor enables different magnetic materials to be combined!

- Dispersed gap design

- Using dispersed gaps reduces the magnetic flux concentration.

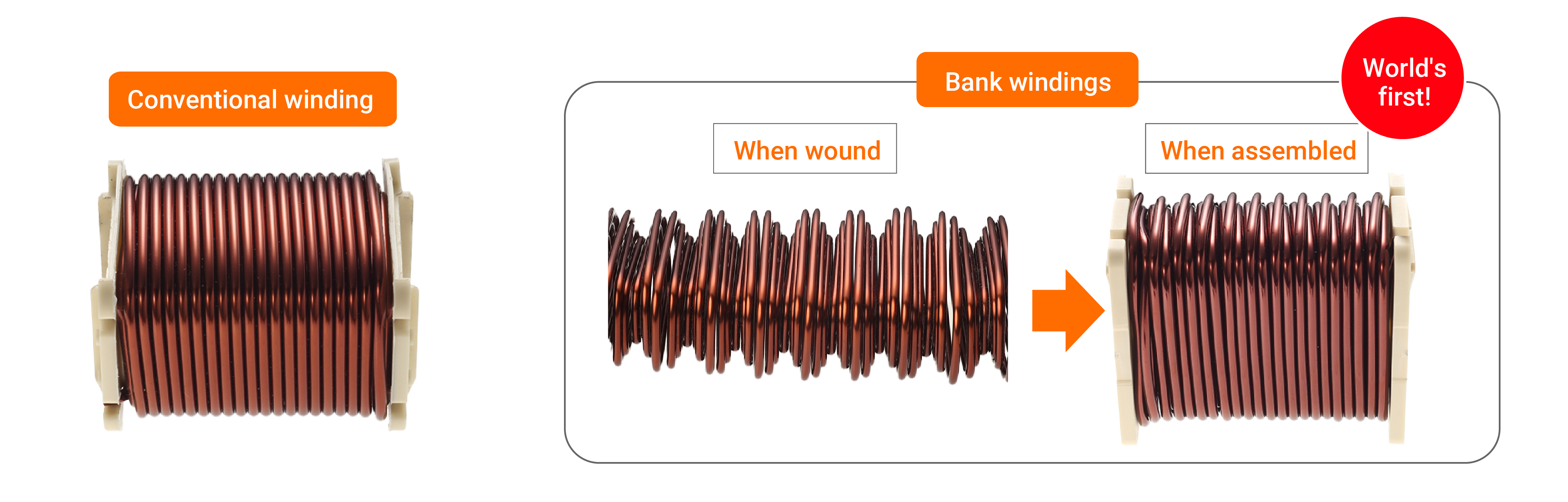

- Bank coil (patented manufacturing method)

-

- High withstand-voltage structure with minimal electric potential difference between windings

⇒ Improves reliability and safety - Greatly reduced stray capacitance (Cs)

⇒ Less than 1/10 of previous model - Higher resonance frequency range and stable inductance over a wide range

⇒ Ideal for high-frequency drive of power supply switching

- High withstand-voltage structure with minimal electric potential difference between windings

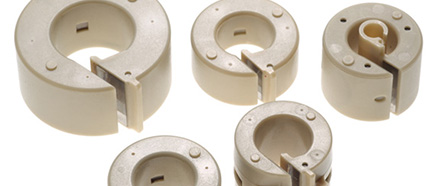

- Hybrid cores (patented manufacturing method)

-

- Enables the design of cores optimized for the unit, such as using an amorphous thin film in C cores, and grain oriented electrical steel in I cores.

⇒ Can meet a wide range of needs by combining different magnetic materials

⇒ Optimized designs contribute to low noise and high efficiency

⇒ Enables compact, lightweight, low-loss designs - Usable with low-loss materials suitable for high frequency drive

⇒ Compatible with future higher unit frequencie

- Enables the design of cores optimized for the unit, such as using an amorphous thin film in C cores, and grain oriented electrical steel in I cores.

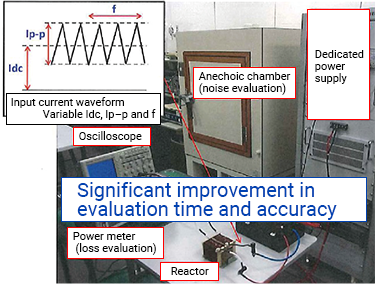

- New evaluation device

-

- Enables easy customer evaluation of mounting characteristics (loss and noise)

⇒ Shortens product evaluation process

- Enables easy customer evaluation of mounting characteristics (loss and noise)

Fundamental Technologies

Bank windings

frequency characteristics (at 0A)

Hybrid core

I Core

Materials used

- Grain-oriented electrical steel

- Non-oriented electrical steel

- Iron powder core

C Core

Materials used

- Grain-oriented electrical steel

- Non-oriented electrical steel

- Iron powder core

* A hybrid core contains a combination of different magnetic materials

| Optimization | Optimized designs contribute to low noise and high efficiency | |

|---|---|---|

| Compact and lightweight | Use of high flux density magnetic foil materials reduces size and weight (15% less compared with previous model) | |

| Multiple gap structure | Reduces flux leakage from gaps, reducing overcurrent loss |

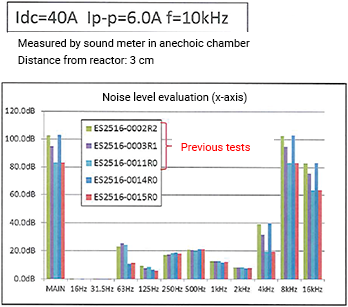

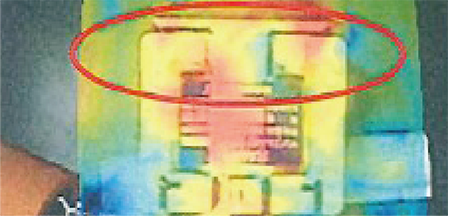

Evaluation technology (characteristics and noise)

Introduction of new evaluation device

Sample Evaluation

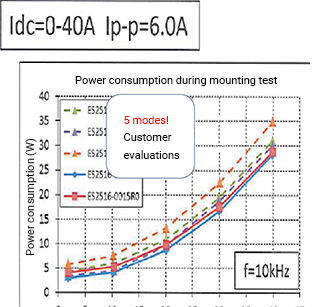

Mounting test results

Noise test results

Design reference

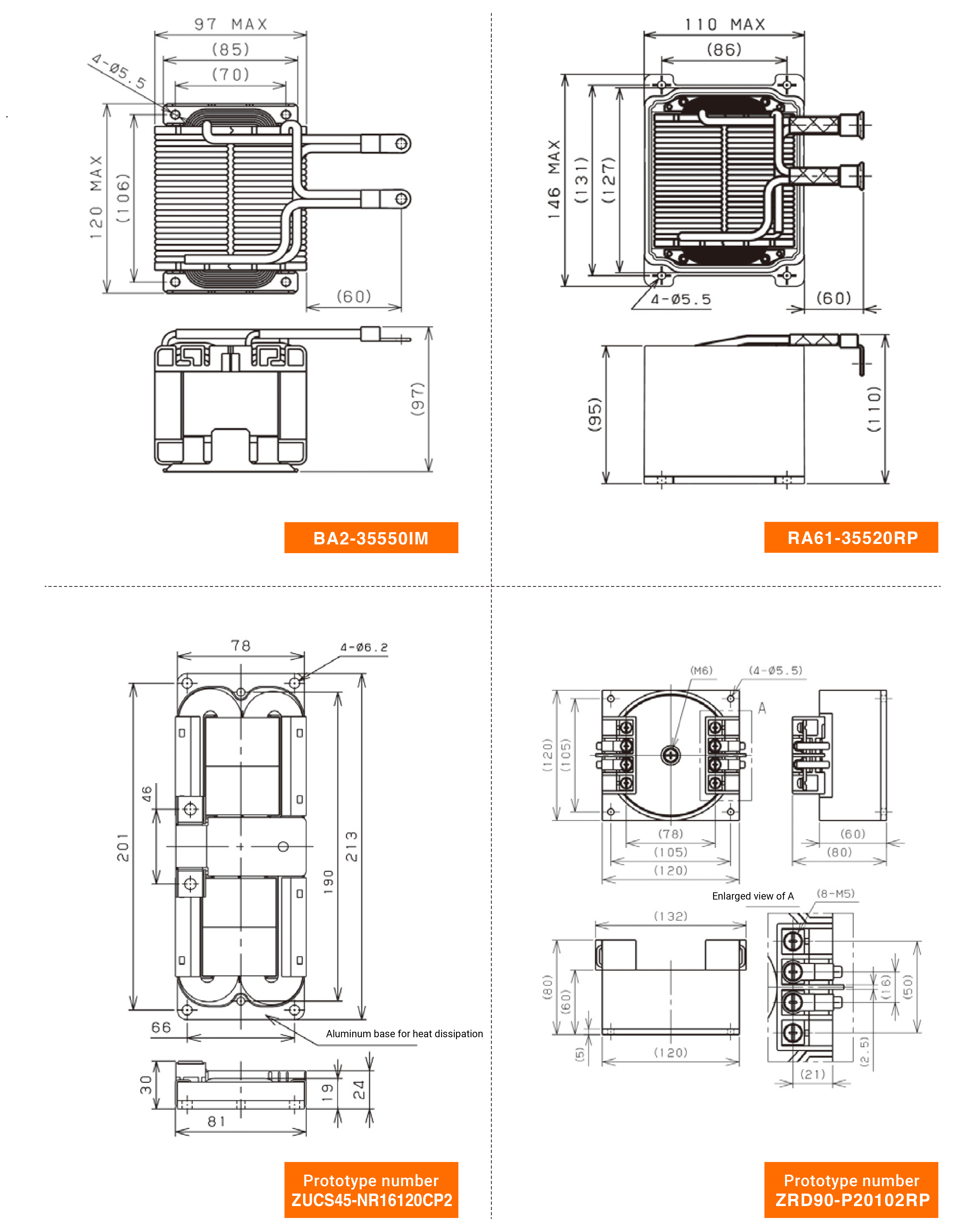

Electrical characteristics and dimensions

(Target values estimating actual values for prototypes under development)

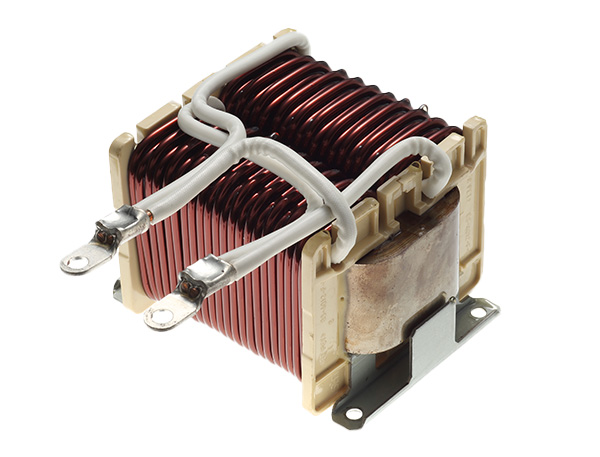

Appearance

Please feel free to ask about other products not shown. We can customize to your specifications.

DC superimposition characteristic(L-I at 20kHz)